FLOATING PRODUCTION SERVICES

HBA has an extensive track record in developing, building, owning, and operating Floating Production units, including FPSOs (Floating Production, Storage, and Offloading units), FSOs (Floating Storage and Offloading units), and FSRUs (Floating Storage and Regasification Units). Specialising in medium-sized converted or refurbished FPSOs and early production solutions, HBA combines strong commercial awareness, technical expertise, and a robust network of partners and contractors to drive projects toward early commercialisation. With a focus on Asia, Africa, and South America, HBA collaborates with world-class technology providers to adapt its floating production expertise to create class-approved offshore renewable products such as FAPSO (floating ammonia plants) and FSS (floating substations). These innovations aim to unlock offshore energy potential, reduce costs, and shorten project schedules.

OFFSHORE TRANSPORT & INSTALLATION

HBA also excels in offshore transport and installation, leveraging its in-house engineering, chartering, and marine operations expertise to support a diverse range of marine and subsea projects, including FPSOs, floaters, and other complete project logistics. By integrating its technical knowledge and operational capabilities, HBA ensures efficient project execution from concept to completion, enabling the seamless deployment of floating production units and offshore infrastructure.

EPICOM Services

HBA specializes in the execution of floating production systems EPCI projects covering project management, customer relationships management, design and detailed engineering, procurement, construction and commissioning, and offshore installation works. Our project execution model provides strong emphasis on HSE, Quality, Sustainability and Compliance in all areas of customer coordination, design, procurement, construction, installation and commissioning.

HBA Marine Logistics provides various types of DP2 offshore vessels, DP3 accommodation & heavy lift / construction assets to support projects and offshore infrastructures development. HBA commits to around the clock support services to ensure efficient complex marine operations, and carried out in time, in a safe and sustainable manner.

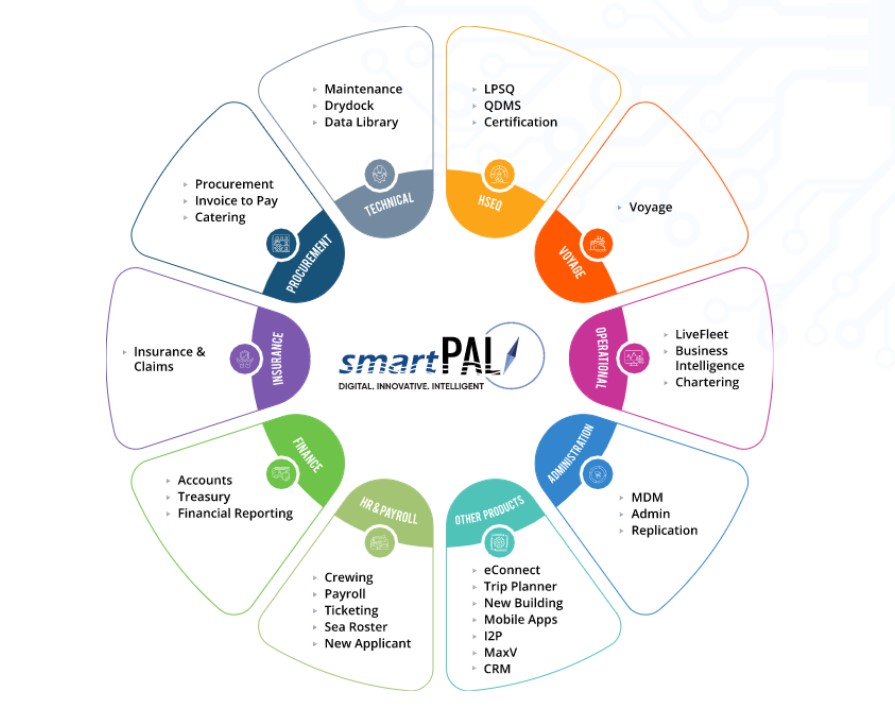

HBA leverage on its in-house engineering, chartering, and marine operations expertise to support a wide range of subsea and marine installation projects, while offering state-of-the-art, built for purpose vessels and equipment. Our integrated technical management capabilities; agile and responsive approach; and high-spec marine assets backed by state-of-the-art enterprise resource management systems (PAL3, accredited by DNV for ISO & ISM) provide a safe and economical means of executing our clients’ subsea solutions.

- HBA select the most suitable vendors, contractors, and shipyards from all over the world to undertake the conversion of existing vessels or construction of new hulls, fabrication of topsides module facilities, fabrication of mooring system components, manufacturing of offloading equipment and installation of all completed equipment on board the units.

- HBA has developed strong relationships and experience with leading contractors and shipyards from all over the world and select the most optimal solution while outsourcing the construction of hulls, fabrication of the topsides facilities, mooring system components, manufacturing of offloading equipment and installation of all completed equipment on board the units.

- HBA has a strong in-house project execution resource pool comprising project engineers, construction superintendents and managers, safety and quality personnel, supply chain competence, project planners, estimators and cost controllers, mechanical completion, commissioning, and start-up experts.

- Upon successful completion of the systems and facilities at the offshore location, we hand over the floating production systems to either customers or our operations teams for the start of the production service.

Engineering

HBA provides bespoke engineering services across the entire project execution value chain. The singapore based senior and lead engineers working from Singapore are backed by our OilTech 21 design office in India. This combination of high-end work coupled with cost effective technical design and support services provides HBA with a unique competitive edge of efficiency, cost and ability to scale projects.

HBA provides bespoke services centered on floating solutions such as:

- Marine and naval architecture including all aspects of floater and tanker specification

- Mooring system design

- Turret design and specifications

- Top-side design

- Power system designs and optimization

- E-house and control systems

- Gas handling and processing

- Interfaces management and controls

- Offshore AC/DC Substations

HBA has experience in wide range of projects and assignments. This combined with the decades of operating experience ensures that our designs are current, and operator friendly. A solid base of engineering standard documentation ensures a consistent and optimized approach of engineering.

Project Execution

Floating Production

From engineering to procurement of materials and equipment, and fabrication and integration, to finally testing the facility before hand over to the Operations team, project execution is complex. It requires extreme discipline to ensure that HBA teams, subcontractors and yards work together seamlessly to deliver on time and on budget

HBA project execution division is responsible for ensuring a structured, methodical, disciplined, executable approach to project execution. HBA has a strong in-house resource pool comprising project engineers, construction managers and supervisors, safety and quality personnel, supply chain engineers and managers, project planners, estimators and cost controllers, mechanical completion, commissioning, and start-up engineers and managers.

HBA project execution utilises the latest software such as primavera and PEGASUS and is armed with an extensive data base of executed projects. This historical database provides easy access to critical data allowing quick benchmarking alignment and estimating.

Frontloading of engineering and procurement activities is essential in project execution to ensure sufficient time for construction teams to execute plans and build the facility. This in turn allows for a thorough and timely commissioning process where individuals who combine the best of project and operations experience test the unit adequately to ensure a smooth start-up.

Offshore heavy lift & INSTALLATION

Highly specialized vessels are typically used for the installation of submarine cables and production platforms as well as jackets and monopiles in the case of offshore wind development.

As the demand for sustainable technology grows in the offshore subsea industry, so does the need for cleaner, renewable features on enabling equipment and their accompanying vessels. Our industry remains critical to powering the global economy, and the transition to clean, more environmentally friendly practices and products represents a robust opportunity for organizations around the world.

HBA provides tailored heavy lifting solutions which includes offshore topsides and windfarm foundations.

- 2400 days of vessels charter since 2018, including:

- 3 x IMR / Saturated Diving Support Vessels

- 1 x DP3 Accommodation Barge (600 pax) for an upgrade and start-up project

- 2 x 250 BP DP2 AHTS for deep water (1600 m ) & anchor handling / ROV operations

- Wind Farm installation Vessels

Ship Management

HBA Ship Management group provides operations, technical maintenance, services, as well as management of vessels’ marine crew. HBA services include commercial management, chartering and financial administration.

Operations & Asset Management

HBA’s AMO group controls the risk of operation and assures stability and continuity of operations and production and safety throughout all activities.

HBA AMO strategy is risk based, incorporating best practices and ALARP principles. By understanding the balance between the cost of failure and the cost of maintenance, our teams can focus the right resources on the right equipment at the right time and provide significant cost reduction to the overall OPEX throughout the project lifecycle.

HBA AMO teams are assigned to the project team early on ensuring operating input throughput the project development and resulting in a smooth and efficient commissioning and start up

New Build Projects

HBA in house New-Building group offers its customers a highly experienced, multidisciplinary team able to complete complex specifications & contract review. The team is highly knowledgeable in offshore vessels newbuilding projects and consists of Naval Architects, Mechanical engineers, Electrical engineers, Structural engineers and other key disciplines such as superintendents and Captains, ensuring all details are covered.

PAL SYSTEM

- HBA is committed to leverage its renewable energy knowledge for generation of green hydrogen, green ammonia and other global decarbonizing initiatives.

- The PAL software has 16 interdependent modules including: CMMS ( Computerised maintenance management system) , Crewing , HR, budgeting rotation, dry docking, coupled with strong and reliable satellite communication. HBA AMO receives instantaneous operating data and records allowing for timely intervention and operational efficiency.